Product Details

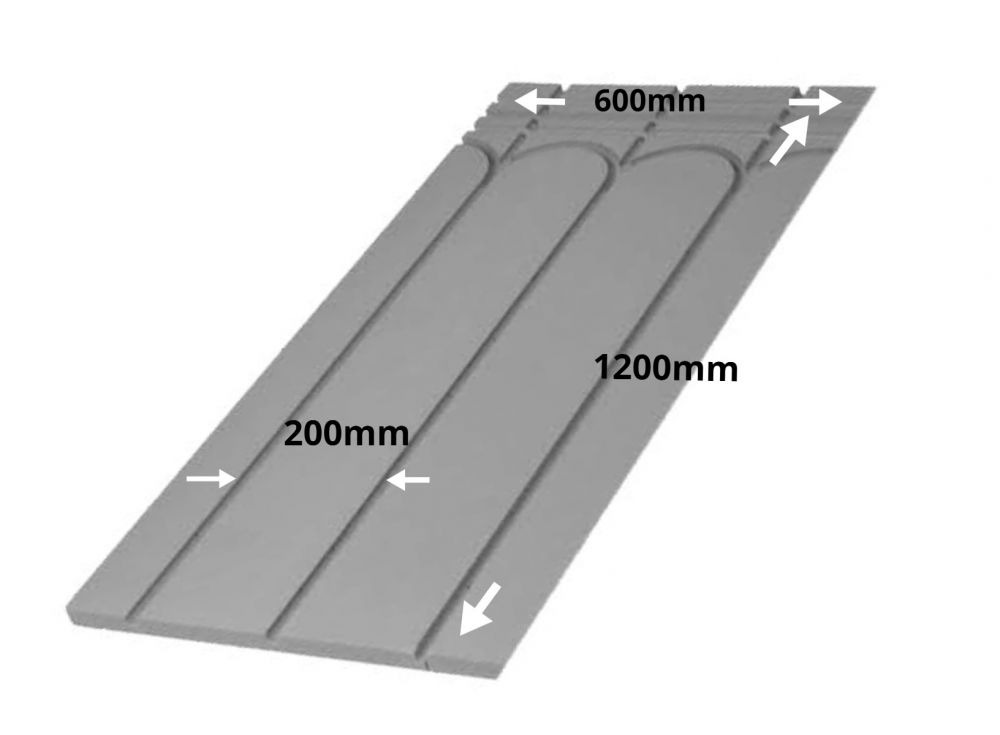

These XPS300 25mm solid-floor panels are the ideal solution for the installation of an underfloor water heating system with a tiled-finish floor covering. This product is suitable for both domestic and commercial use. The panels have been made from super-insulated extruded polystyrene, making them ideal for direct use under tiled flooring. The panels are 1,200mm x 600mm x 25mm pre grooved to take 16mm pipe @ 200mm centres and must be installed onto a suitable existing subfloor, such as solid concrete or screeded floors. They are also suitable for structurally sound wooden subfloors such as 18mm exterior plywood.

After bonding the floor and panels simply stick down with flexible tile adhesive and allow to set. Then cover with a 3mm-5mm self levelling screed before the final floor covering.

Coverage:- 1200mm x 600mm x 25mm = 0.72m2

-- Remove all contaminants, dirt, grease etc from the substrate and make dust free.

-- Loose lay the boards across the floor and number the boards on the upper face to identify position of each board, making sure the pipework runs are calculated correctly to reach manifold position.

-- Uplift the numbered boards and prime the underside of the boards with Ultra Floor Prime-IT MSP bonding primer. This should be applied by brush or roller in a thin film. Allow to thoroughly dry to a clear green film ensuring primed face does not come into contact with other boards, walls or subfloor until it is ready to be bedded.

- -Drying time will depend upon ambient conditions but is typically between 1 and 4 hours.

-- Whilst the primer on the boards is drying commence with priming of the substrate using UltraFloor Prime-IT MSP. The primer should be diluted 3 parts water to 1 part primer and allowed to fully dry.

-- Apply flexible tile adhesive to the subfloor using a notched trowel to give a minimum 3mm adhesive bed. Bed the boards, primed side down, into the adhesive and ensure compression of adhesive ridges, ensure full compression of the adhesive to give a void free full adhesive bed. Additional use of screws and washers is recommended over timber substrates where needed, fixed at every 300mm. Allow to cure for approximately 4 hours to ensure the adhesive has gone through its initial set before carrying out any further works.

-- Pipe work may be fitted into the boards once they are all secure. Where possible this is best left until the following day. It is recommended that the pipe system is checked for leaks and correct water pressures prior to tiling over.

-- Prime the upper face of the boards with Ultra Prime-IT MSP bonding primer. This should be applied by brush or roller in a thin film. Allow to thoroughly dry to a clear green film, (approx 1-4 hours).

-- Apply Ultra Floor Level-iT 2 two part smoothing compound over entire floor area, making sure all voids and gaps are completely filled, the levelling compound should encapsulate the whole floor and cover the board with a 5mm layer on top.

-- Allow to cure for 24 hours prior to carrying out any tiling. Cold and/or humid atmospheres will delay the curing of Level-iT 2 so allowances should be made accordingly.

-- Prime the cured Level-iT 2 using Ultra Floor Prime-IT MSP diluted with 3 parts water to 1 part primer. Allow to thoroughly dry.