Imagine stepping into a consistently warm room, without a single cold spot underfoot. That’s the magic of a well-designed underfloor heating system!

An underfloor heating manifold is the backbone of an efficient UFH system, a pivotal component that ensures heated water circulates flawlessly throughout your home’s flooring. In this article, we’ll delve into the overall function of an underfloor heating system, its components, installation processes, and its integral role in optimising home heating efficiency.

Key points:

- Understand the essential role and mechanics of an underfloor heating manifold.

- Explore the key components that make up a manifold, including valves and gauges.

- Learn how manifolds control heating zones and maintain consistent temperatures across different rooms.

- Insightful tips on the best practices for manifold installation and placement.

- Maintenance advice to ensure your underfloor heating system operates at peak efficiency.

What is an Underfloor Heating Manifold?

An underfloor heating manifold acts as a central hub in a home heating system, efficiently distributing heated water throughout various underfloor heating zones. This crucial component connects directly to the heat source, whether it’s a boiler or a heat pump, ensuring that each section of the underfloor heating system receives water at the optimal temperature and flow rate.

For wet underfloor heating systems, for example, by managing the water distribution so precisely, the manifold facilitates a consistent and comfortable temperature in different areas or rooms, each controlled by its own thermostat.

These are some of the features that you want to look for in a manifold:

- A pump that rotates 90 degrees and has a slim profile that fits easily into the manifold cabinet.

- That it is easily transferable from one side to the other without the need to adjust the unit.

- Is able to pump longer loops than traditional manifold pump sets.

- A flow temperature gauge incorporated into the flow bar.

- A blender valve with a temperature setting range between 25 to 80 degrees.

Underfloor Heating Manifold Kit Essentials

There are a number of unique features that make up an underfloor heating manifold:

1. Flow and Return Gauges

These gauges are essential for monitoring the temperatures and flow rates within the system. The flow gauge indicates how much water is entering each zone, while the return gauge measures the temperature after the water has circulated through the pipes.

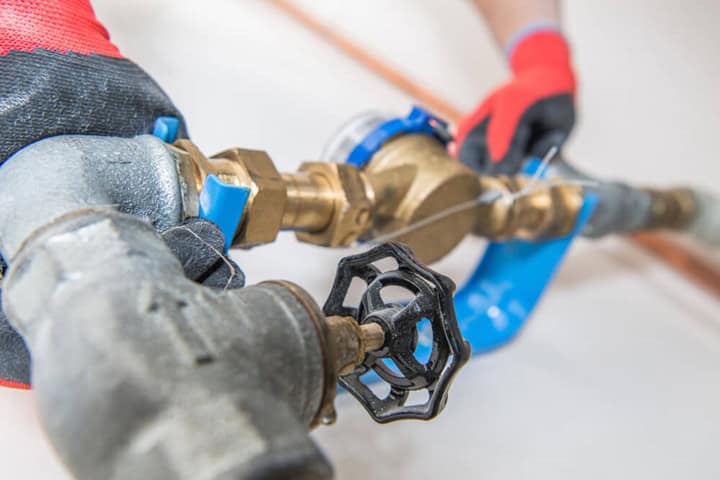

2. Adjustment Valves

These valves are critical for fine-tuning the water flow to each heating zone. By adjusting these, users can ensure that each area of their home receives the right amount of heat, tailored to its specific needs.

3. Actuators and Zone Control

Actuators are vital for controlling which zones of the house receive heat at any given time. Connected directly to the zone’s thermostat, actuators open and close to allow water to flow through the underfloor pipes as needed.

4. Pressure and Air Ventilation

A pressure gauge is installed to monitor system pressure, crucial during setup and maintenance checks. Additionally, manual air vents are included to release any air trapped in the system, ensuring efficient operation and preventing air locks.

5. Filling and Draining Facilities

The manifold includes valves for filling the system with water initially and draining it for maintenance. These are strategically placed to facilitate easy access and efficient operation.

How Underfloor Heating Manifolds Work

The manifold is equipped with several ports, typically ranging from 2 to 12, corresponding to the various zones it controls. Each port has a pair of connections for the flow and return of water. The system is designed so that when a particular zone requires heating, the thermostat signals the actuators to open the necessary valves. This process allows heated water to flow into the underfloor pipes, circulate through the zone, and then return to the manifold where the temperature and flow can be reassessed and adjusted as needed.

The Role of Manifolds in System Efficiency

Underfloor heating manifolds are not just about distributing heat; they play a crucial role in the energy efficiency of the heating system. By ensuring that each zone receives precisely the right amount of heat, manifolds help to minimise waste and improve overall system performance. Their ability to manage multiple zones individually allows for tailored heating schedules, reducing energy consumption while maintaining comfort.

Underfloor Heating Manifold Installation

Installing an underfloor heating manifold requires specific attention to ensure the system operates efficiently.

Initially, the manifold must be correctly connected to the heat source, such as a boiler or heat pump. This connection is crucial as it supplies the warm water necessary for heating. During the installation, integrating a blending valve can effectively mix the hot water with cooler returning water, optimising the system’s efficiency by reaching the desired temperature settings.

Setting the appropriate flow rate for each circuit is integral in its performance. This adjustment ensures that every underfloor heating zone receives precisely the right amount of heat, tailored to the specific thermal characteristics of each room, including factors like floor construction and expected heat loss.

Ideal Placement for Manifolds

For maximum efficiency, the underfloor heating manifold should be centrally located relative to the heating zones it serves. This central placement minimises the length of the pipes required, which helps maintain consistent water temperatures throughout the system. In larger properties, using multiple manifolds may be beneficial to ensure even heating across expansive areas.

Maintenance

Despite the low maintenance nature of underfloor heating manifolds, regular checks are critical to prolong the system’s lifespan and functionality. It is advisable to hire a professional to inspect the system annually to prepare it for the heating season. Additionally, periodically running the system, even during warmer months, can keep the mechanical components, like the water pump, well-lubricated and functioning properly.

Preventing Air Traps

Air trapped within the underfloor heating system can affect its performance. Regularly bleeding the system using the air vents on the manifold can prevent this issue. Modern manifolds often feature automatic air vents, which further simplify maintenance by automatically expelling trapped air.

Monitoring System Health

Regular monitoring of the system’s pressure and flow metres is pivotal when maintaining its performance. These metres, typically mounted on the manifold’s flow rail, help gauge the system’s overall health and ensure it is operating within the optimal pressure range, usually between one and two bars.

Installation Dos and Don’ts

- Do: Ensure that the manifold is accessible for future maintenance. Avoid enclosing it within plasterboard walls where access can be challenging.

- Don’t: Neglect to consider the spatial requirements during the early design phase. Adequate space is needed not only for the manifold but also for associated electrical supplies, thermostat wiring, and primary pipework.

System Testing and Final Setup

After the manifold and circuits are connected, a thorough pressure test is essential to ensure all connections are secure and the system is leak-free. While some aspects of installation may be suitable for a DIY expert, the final connections should always be made by a certified professional to guarantee system integrity and safety. Contact us today for more details.

How much does an Underfloor Heating Manifold?

The cost of underfloor heating manifolds can vary depending on the number of ports and the specific model required for your heating system. Typically, prices range from £95 (£114 including tax) for simpler models, up to £265 (£318 including tax) for more complex units with additional ports.

Email info@underfloorheatingtradesupplies.co.uk or call us today on 01625 569528 and see how we can help.

All manifolds should be compliant with the Water Regulations Advisory Scheme (WRAS) to ensure they meet the necessary legal and safety standards. When selecting a manifold, it’s crucial to consider both the upfront cost and the long-term benefits of choosing a high-quality, durable unit that will efficiently manage your home’s heating for years to come.

Underfloor Heating Manifolds Made Simple

In conclusion, an underfloor heating manifold is central to managing an efficient home heating system, ensuring consistent warmth across different zones. Proper installation, strategic placement, and routine maintenance are crucial for maximising its performance and longevity. While the initial cost may vary, investing in a quality manifold that meets safety standards will provide long-term benefits, making it a smart and sustainable choice for enhancing home comfort and efficiency.

Further reading

With so many methods to integrate underfloor heating manifolds, here is some additional articles to check out on our blog:

- Explore more experimental heating methods, such as combining ground source heat pumps with underfloor heating.

- Don’t let the pressure get on top of you! Understand how underfloor heating pressure works for a sufficient UFH test before beginning the warmup.

- Underfloor heating does not have to be restricted to one room – check out the intricate methods of multi-zone heating.

FAQs

Do I need a manifold for underfloor heating?

Yes, a manifold is essential for underfloor heating systems as it distributes the hot water evenly across the various circuits of the heating system.

Where is the best place to put the underfloor heating manifold?

The best place to install the underfloor heating manifold is a central location within the area being heated. It should be easily accessible for maintenance and preferably located in a utility room or cupboard to keep it out of sight.

Sources

Water Regulations Approval Scheme. (n.d.) WRAS Approvals. [online] Available at: https://www.wrasapprovals.co.uk/ [accessed 08/07/24]